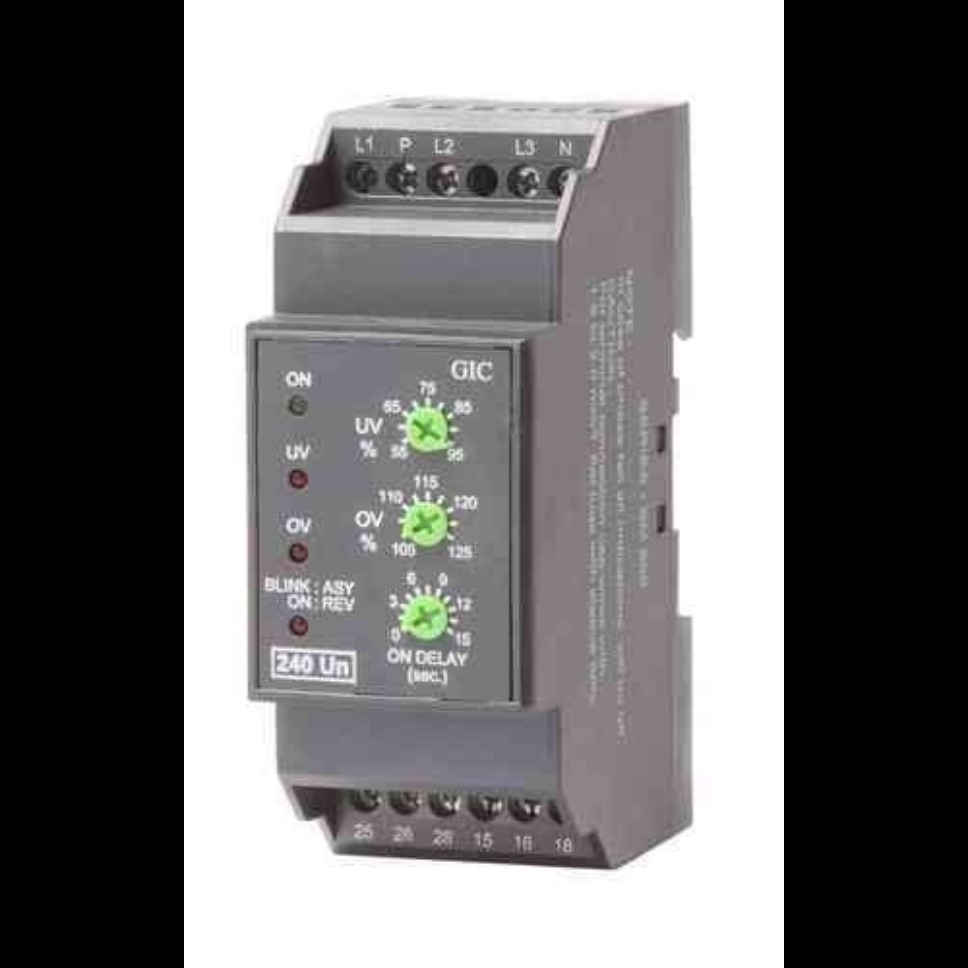

A single-phase preventer is a protective device used in three-phase electrical systems to safeguard equipment, particularly induction motors, from damage caused by a 'single-phasing' fault. A single-phasing fault occurs when one of the three phases of the power supply is lost, but the motor continues to run on the remaining two phases. This condition causes a significant imbalance in the current, leading to severe overheating and eventual burnout of the motor windings. Working Principle A single-phase preventer works by continuously monitoring the three-phase supply. It typically operates on the principle of detecting a voltage or current imbalance. There are two main types: Voltage-Sensing: This type constantly checks the voltage across all three phases. In a balanced system, the voltage between any two phases is equal. When one phase is lost, this balance is disturbed. The preventer detects this change and de-energizes a control relay. The contacts of this relay are connected in series with the motor's starter coil. When the relay de-energizes, it opens the circuit to the starter, shutting down the motor. Current-Sensing: This type monitors the current flowing through each phase. When a single-phasing fault occurs while the motor is running, the current in the two remaining phases increases significantly (up to 1.73 times the normal current) to compensate for the lost phase. The preventer detects this high current and trips the motor circuit. Essentially, a single-phase preventer acts as a sentinel, immediately cutting off power to the motor when it senses an abnormal condition, such as a missing phase, unbalanced voltage, or phase reversal, before it can cause permanent damage. Applications Single-phase preventers are essential for any equipment that relies on a three-phase power supply. Their applications are widespread in industrial and commercial settings, including: Pumping Systems: They protect submersible and surface pumps used for water supply, irrigation, and industrial processes. Compressors: They are vital for air compressors in workshops and refrigeration units to prevent motor burnout. Conveyor Belts: In manufacturing and material handling, they protect the motors that drive conveyor systems. Industrial Machinery: They are used on a variety of three-phase industrial machines, such as lathes, milling machines, and other heavy-duty equipment. HVAC Systems: They protect the motors in large air conditioning and ventilation systems. #sppr #L& T #Schneider #multispan #gic #trending #sparkelectric #dealers #motor

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sparkelectric.co.in/latest-update/single-phase-preventer-dealers-in-noida-delhi-ncr-sparkelectric24/40

Single-Phase Preventer dealers in noida & Delhi/NCR..... @sparkelectric24 .......................

2025-08-08T16:33:28

A single-phase preventer is a protective device used in three-phase electrical systems to safeguard equipment, particularly induction motors, from damage caused by a 'single-phasing' fault. A single-phasing fault occurs when one of the three phases of the power supply is lost, but the motor continues to run on the remaining two phases. This condition causes a significant imbalance in the current, leading to severe overheating and eventual burnout of the motor windings. Working Principle A single-phase preventer works by continuously monitoring the three-phase supply. It typically operates on the principle of detecting a voltage or current imbalance. There are two main types: Voltage-Sensing: This type constantly checks the voltage across all three phases. In a balanced system, the voltage between any two phases is equal. When one phase is lost, this balance is disturbed. The preventer detects this change and de-energizes a control relay. The contacts of this relay are connected in series with the motor's starter coil. When the relay de-energizes, it opens the circuit to the starter, shutting down the motor. Current-Sensing: This type monitors the current flowing through each phase. When a single-phasing fault occurs while the motor is running, the current in the two remaining phases increases significantly (up to 1.73 times the normal current) to compensate for the lost phase. The preventer detects this high current and trips the motor circuit. Essentially, a single-phase preventer acts as a sentinel, immediately cutting off power to the motor when it senses an abnormal condition, such as a missing phase, unbalanced voltage, or phase reversal, before it can cause permanent damage. Applications Single-phase preventers are essential for any equipment that relies on a three-phase power supply. Their applications are widespread in industrial and commercial settings, including: Pumping Systems: They protect submersible and surface pumps used for water supply, irrigation, and industrial processes. Compressors: They are vital for air compressors in workshops and refrigeration units to prevent motor burnout. Conveyor Belts: In manufacturing and material handling, they protect the motors that drive conveyor systems. Industrial Machinery: They are used on a variety of three-phase industrial machines, such as lathes, milling machines, and other heavy-duty equipment. HVAC Systems: They protect the motors in large air conditioning and ventilation systems. #sppr #L& T #Schneider #multispan #gic #trending #sparkelectric #dealers #motor

2025-08-08T16:33:28

Submit Your Enquiry