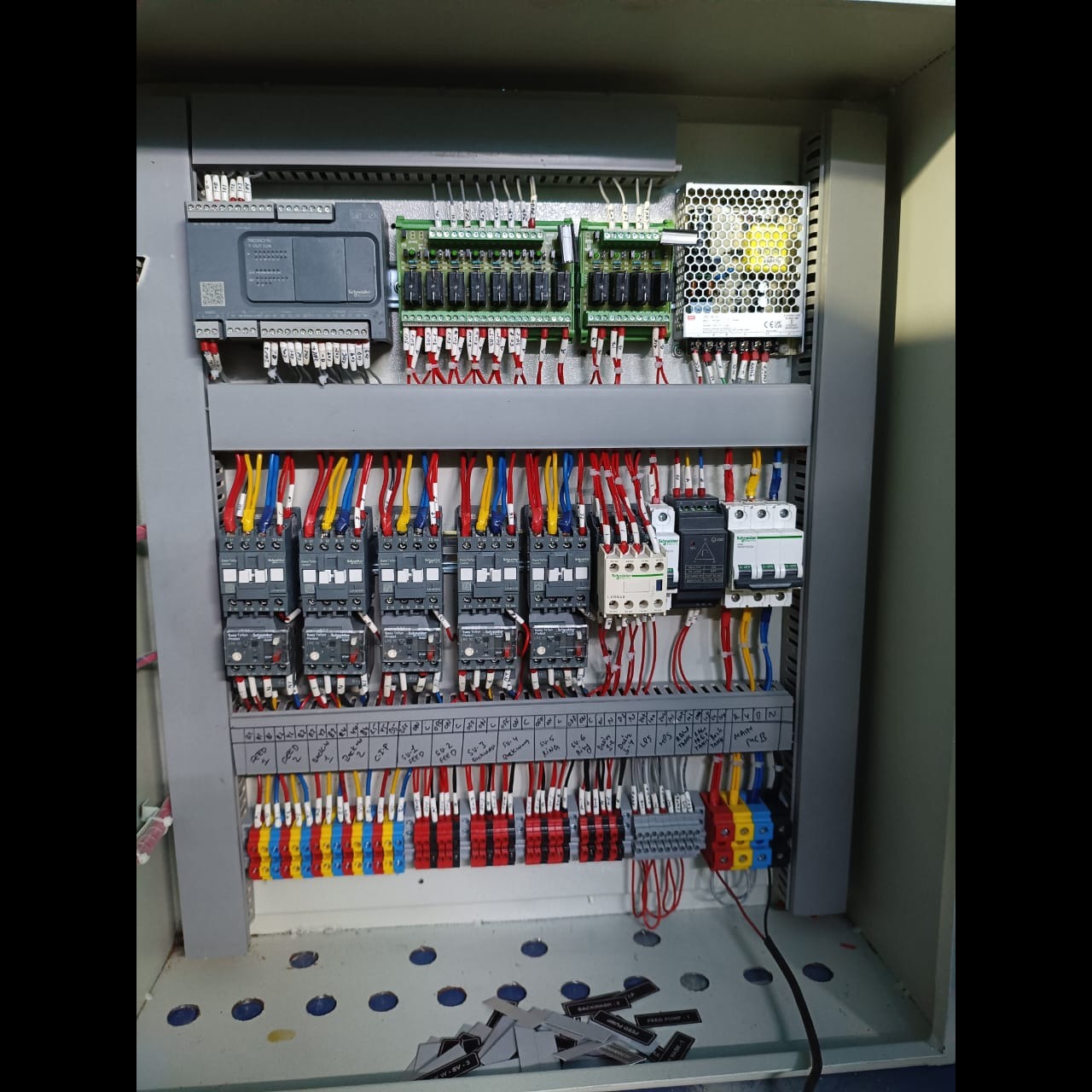

A UF (Ultrafiltration) control panel is an electrical control unit designed to automate and manage the entire operation of an ultrafiltration water treatment plant. It's the central hub that controls and monitors the various components, such as pumps, valves, and sensors, to ensure the system runs efficiently and safely without constant manual intervention. Key Functions of a UF Control Panel The primary functions of a UF control panel are to automate, monitor, and protect the ultrafiltration process. Here's a breakdown of its core functions: 1. Automated Operation The control panel automates the entire UF process, which typically includes several distinct cycles: Filtration: It initiates and controls the flow of raw water through the UF membranes, allowing clean water (permeate) to pass while retaining suspended solids, bacteria, and viruses. Backwash: Over time, contaminants build up on the membrane surface, which reduces filtration efficiency. The control panel automatically triggers a backwash cycle, reversing the water flow to flush out these trapped contaminants and clean the membranes. Chemically Enhanced Backwash (CEB): For more stubborn fouling, the panel can be programmed to inject cleaning chemicals (like sodium hypochlorite or citric acid) into the backwash process at set intervals to enhance the cleaning effect. 2. Monitoring and Display The control panel provides real-time data and status updates, allowing operators to monitor the system's performance. Pressure Monitoring: It constantly monitors pressure at various points in the system, such as feed pressure and transmembrane pressure (TMP), to detect issues like membrane fouling or blockages. Flow Rate Display: Displays the flow rates of both the incoming raw water and the clean permeate to ensure the system is producing water at the desired rate. Fault and Alarm Indicators: The panel uses visual and audible alarms to alert operators to problems like low tank levels, pump overload, or high pressure, allowing for quick troubleshooting. 3. System Protection and Safety Safety features are crucial for protecting expensive equipment and ensuring continuous operation. Motor Protection: It incorporates safety features like overload, dry-running, and single-phasing protection for the pumps, preventing motor damage. Low/High-Level Cut-off: The panel is connected to level sensors in the water tanks. It automatically shuts down the system if the raw water tank is empty or the treated water tank is full, preventing damage to the pumps and overflow. Emergency Stop: An easily accessible emergency stop button allows for immediate shutdown in case of a critical failure. Industrial Applications:- UF control panels are essential in any industry that requires high-quality purified water, as ultrafiltration is a key step in many water treatment processes. Water Treatment: One of the most common applications is in municipal and industrial water treatment plants for producing drinking water. UF systems remove suspended solids, bacteria, viruses, and other microorganisms, often serving as a pretreatment step for reverse osmosis (RO) systems. Food and Beverage: The panels are used to control the clarification and concentration of liquids in the food and beverage industry. Examples include clarifying fruit juices, concentrating whey protein in dairy production, and purifying beer and wine. Pharmaceuticals and Biotechnology: In these industries, a UF control panel ensures the production of highly pure water for manufacturing drugs, and for separating and concentrating proteins, enzymes, and other biological molecules. Textile and Chemical Processing: UF is used for recycling process water and recovering valuable materials from wastewater streams. The control panel automates this process to ensure efficient separation and reuse of chemicals. Oil and Gas: UF control panels are used to manage systems that treat produced water from drilling and hydraulic fracturing, enabling the separation of oil and water and the generation of potable water on offshore rigs.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.sparkelectric.co.in/latest-update/uf-ultrafiltration-control-panel-manufacturer-in-noida-and-delhi-ncr/53

UF (Ultrafiltration) CONTROL PANEL MANUFACTURER IN NOIDA AND DELHI NCR.....................

2025-09-20T15:49:20

A UF (Ultrafiltration) control panel is an electrical control unit designed to automate and manage the entire operation of an ultrafiltration water treatment plant. It's the central hub that controls and monitors the various components, such as pumps, valves, and sensors, to ensure the system runs efficiently and safely without constant manual intervention. Key Functions of a UF Control Panel The primary functions of a UF control panel are to automate, monitor, and protect the ultrafiltration process. Here's a breakdown of its core functions: 1. Automated Operation The control panel automates the entire UF process, which typically includes several distinct cycles: Filtration: It initiates and controls the flow of raw water through the UF membranes, allowing clean water (permeate) to pass while retaining suspended solids, bacteria, and viruses. Backwash: Over time, contaminants build up on the membrane surface, which reduces filtration efficiency. The control panel automatically triggers a backwash cycle, reversing the water flow to flush out these trapped contaminants and clean the membranes. Chemically Enhanced Backwash (CEB): For more stubborn fouling, the panel can be programmed to inject cleaning chemicals (like sodium hypochlorite or citric acid) into the backwash process at set intervals to enhance the cleaning effect. 2. Monitoring and Display The control panel provides real-time data and status updates, allowing operators to monitor the system's performance. Pressure Monitoring: It constantly monitors pressure at various points in the system, such as feed pressure and transmembrane pressure (TMP), to detect issues like membrane fouling or blockages. Flow Rate Display: Displays the flow rates of both the incoming raw water and the clean permeate to ensure the system is producing water at the desired rate. Fault and Alarm Indicators: The panel uses visual and audible alarms to alert operators to problems like low tank levels, pump overload, or high pressure, allowing for quick troubleshooting. 3. System Protection and Safety Safety features are crucial for protecting expensive equipment and ensuring continuous operation. Motor Protection: It incorporates safety features like overload, dry-running, and single-phasing protection for the pumps, preventing motor damage. Low/High-Level Cut-off: The panel is connected to level sensors in the water tanks. It automatically shuts down the system if the raw water tank is empty or the treated water tank is full, preventing damage to the pumps and overflow. Emergency Stop: An easily accessible emergency stop button allows for immediate shutdown in case of a critical failure. Industrial Applications:- UF control panels are essential in any industry that requires high-quality purified water, as ultrafiltration is a key step in many water treatment processes. Water Treatment: One of the most common applications is in municipal and industrial water treatment plants for producing drinking water. UF systems remove suspended solids, bacteria, viruses, and other microorganisms, often serving as a pretreatment step for reverse osmosis (RO) systems. Food and Beverage: The panels are used to control the clarification and concentration of liquids in the food and beverage industry. Examples include clarifying fruit juices, concentrating whey protein in dairy production, and purifying beer and wine. Pharmaceuticals and Biotechnology: In these industries, a UF control panel ensures the production of highly pure water for manufacturing drugs, and for separating and concentrating proteins, enzymes, and other biological molecules. Textile and Chemical Processing: UF is used for recycling process water and recovering valuable materials from wastewater streams. The control panel automates this process to ensure efficient separation and reuse of chemicals. Oil and Gas: UF control panels are used to manage systems that treat produced water from drilling and hydraulic fracturing, enabling the separation of oil and water and the generation of potable water on offshore rigs.

2025-09-20T15:49:20

Submit Your Enquiry