Description

Product details

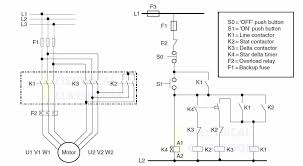

Star Delta Starter Definition: A star delta starter is used for starting 3 phase induction motors, minimizing initial electrical overload by starting in a ‘star’ configuration and then switching to ‘delta’ after reaching a certain speed. Circuit Diagram: The circuit includes a TPDP switch that helps in changing the motor connections from star to delta, facilitating effective control of current and torque during startup. Reduced Starting Current: By using a star delta connection, the starting current is reduced to one-third of what it would be with direct online starting, leading to lower electrical stress. Working Principle: The star delta starter operates on a principle where it starts the motor at a lower voltage and current, then transitions to normal operating conditions to manage power efficiently. Application Suitability: Ideal for situations where low starting torque is adequate, the star delta starter excels in environments like driving centrifugal compressors, where minimal starting current is beneficial. What is Star Delta Starter A star delta starter is the most commonly used method for the starting of a 3 phase induction motor. In star delta starting an induction motor is connected in through a star connection throughout the starting period. Then once the motor reaches the required speed, the motor is connected through a delta connection. A star delta starter begins with the motor’s stator winding connected in star formation. Upon reaching about 80% of its full load speed, the motor transitions to a delta-connected stator winding. A star delta starter is a type of reduced voltage starter. We use it to reduce the starting current of the motor without using any external device or apparatus. This is a big advantage of a star delta starter, as it typically has around 1/3 of the inrush current compared to a DOL starter. The key component of a star delta starter is the TPDP switch, which stands for Triple Pole Double Throw switch. This switch toggles the stator winding from star to delta during startup. For that let us consider, VL = Supply Line Voltage, ILS = Supply Line Current, IPS = Winding Current per Phase, and Z = Impedance per phase winding at standstill conditions. As the winding is star-connected, the winding current per phase (IPS) equals to supply line current (ILS). As the winding is star-connected, the voltage across each phase of the winding is Hence, the winding current per phase is Since here, the winding current per phase (IPS) equals to the supply line current (ILS), we can write, Now, let us consider the situation where the motor gets started with delta-connected stator winding from same three-phase supply points, Advantages of Star Delta Starter The advantages of star delta starters include: Inexpensive It produces no heat and doesn’t require a tap-changing device, thereby increasing efficiency. Starting current reduced to 1/3 of direct online starting current. Produce high torque per ampere of line current. Disadvantages of Star Delta Starter The disadvantages of star delta starters include: The starting torque is reduced to 1/3 of full load torque. A particular set of motors is required. Application of Star Delta Starter As discussed in the above advantages and disadvantages, a star-delta starter is most suited to applications where the required starting current is low and where the line current draw must be at a minimum value. The star delta starter is not suitable for applications where high starting torque delivery is required. For these applications, a DOL starter should be used instead. If the motor is too heavily loaded, there will not be enough torque to accelerate the motor up to speed before switching over to the delta position. An example application for a star delta starter is a Centrifugal compressor.